[[RAW HTML]]

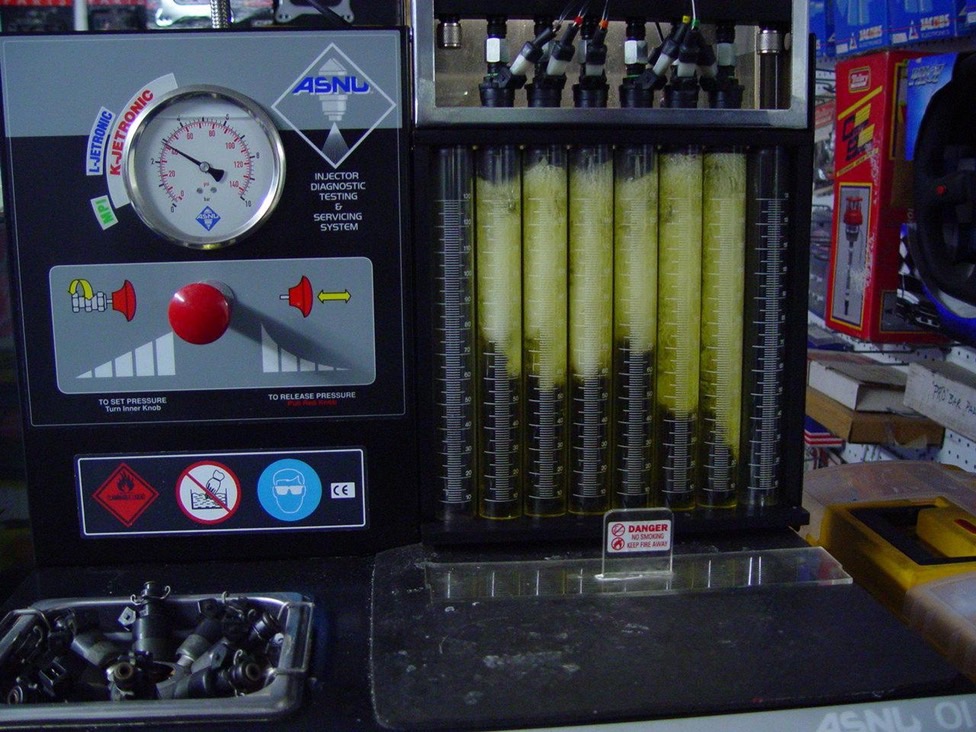

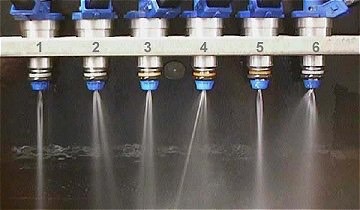

- FAIR - but weak

- BAD - split spray pattern

- BAD - split spray pattern

- BAD - jetting on left side

- GOOD

- BAD - feathering at top of spray

Electronically-controlled fuel injectors are very durable, precise metering systems capable of pulsing for millions of cycles.

The most common problem with injectors is they accumulate a buildup of wax, tars and olefins inside the injector and on the pintle/seat area. These types of debris buildup will restrict the flow of fuel through the injector. These are elements of gasoline that are baked on the injector after the engine is turned off and the temperature climbs to the highest point. The injectors are manufactured to such close tolerances that a 5-micron buildup (a human hair measures 40 to 90 microns) will reduce the flow up to 25%. Utilizing a chemical harsh enough to remove this buildup will also possibly damage internal injector o-rings and seals. It is unknown what effect the chemical cleaners have on the oxygen sensors or catalytic converters.

The only cleaning method recognized to cleanse these precise metering devices without damaging the components are the same methods recognized by the medical profession and other high-tech industries - ultra sonics.

This procedure bombards the injector with ultrasound waves that break up the contaminates while the injector pulses. The debris is then carried out of the injector by a biodegradable chemical.

Utilizing this procedure, the flow rate of the injector is returned to as-new condition.

Before Cleaning

After Cleaning

Ultrasonic Cleaning

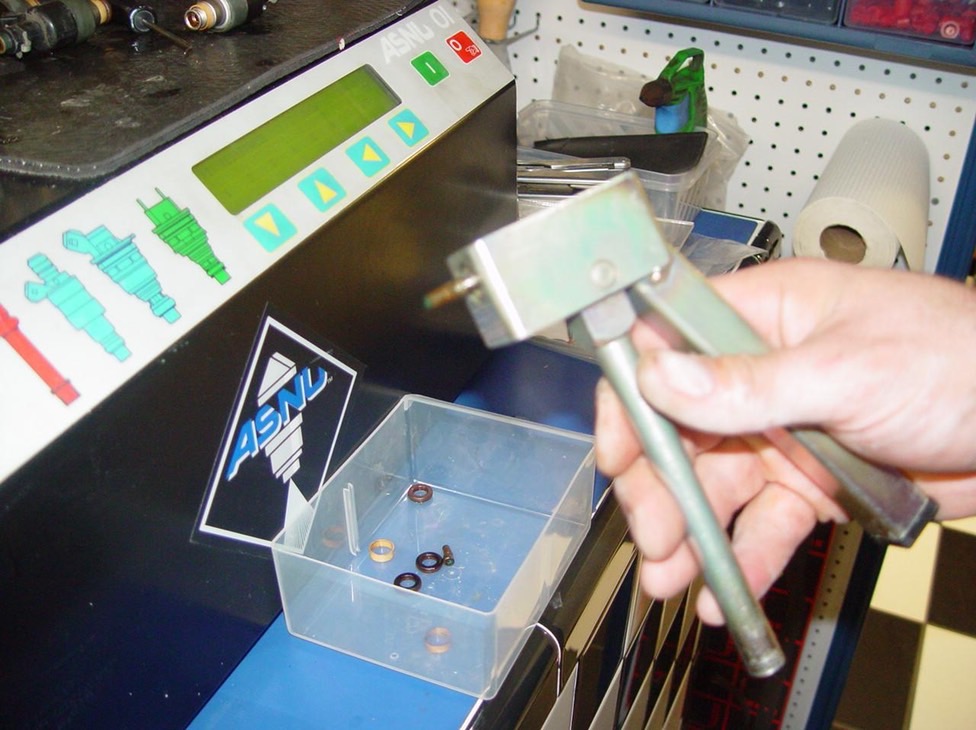

Removal of Internal Filter