Big Block Ford

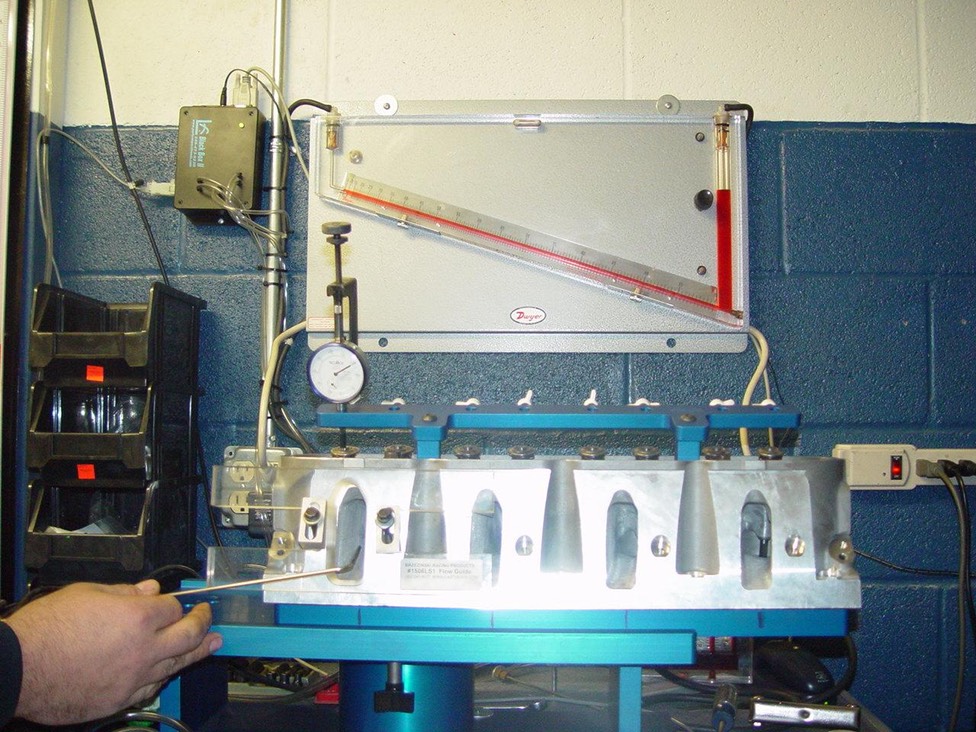

Basic cylinder head porting will improve the performance of any production cylinder head by removing flaws that come through mass production. Basic porting does not attempt to correct any design or engineering deficiencies. Once your porting project turns to that, you're beyond the scope of basic porting techniques.

Why is basic port work important to your engine's performance? It reduces the restriction in the engine's intake and exhaust tracts. Reduce that restriction and you let more air into the cylinders. If you have more air, you can add more fuel. The result is increased horsepower.

The area of the valve guide that protrudes into the intake or exhaust port is always a place where sharp edges and restriction to flow are found. A basic porting project seeks to smooth those sharp edges.

A more significant point of restriction is where the intake or exhaust port floor curves down to meet the valve seat. Called the "short side radius," it is also a place where sharp edges and roughness pose a threat to flow. In this cutaway of a production cylinder head, the short side radius has not one but two very sharp edges.

Most of the work in a basic porting project is focused on reducing those restrictions which are caused by:

![]()

"Steps" that may obstruct intake air flow as it transitions from the intake manifold to a smaller intake port entry in the head

![]()

Casting bumps, ridges or other marks, such as those you may find on port floors or roofs

![]()

Sharp edges, such as those you will find around the valve guide bosses at the top of the valve pockets

![]()

The point where the intake port floor curves down to the valve seat.