The FH2 DPF cleaning System is revolutionizing the DPF cleaning industry.

An innovative, compact design cleans all particulate filter types for cars, light, medium and heavy trucks, buses, stationary power plants and off road equipment equipped with a diesel particulate filter. It efficiently removes virtually all PM-10 (soot & sulphated ash) from the channels of the filter restoring the DPF to serviceable conditions.

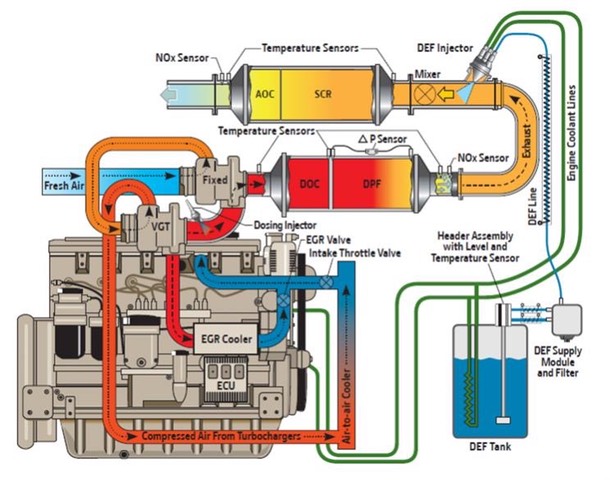

Most DPF cleaning Systems are designed to clean modular canister style filters found on heavy trucks that when the DPF is removed, the full inlet and outlet surfaces of the filter are easily accessible. Many diesel particulate filter designs such as those on cars, light and medium sized trucks have the DOC and DPF housed in a sealed housing in conjunction with small diameter exhaust tubing preventing access to the inlet or outlet surfaces of the filter making it make it difficult or impossible to clean. In these instances the DPF must be cut open, cleaned and welded back together again to restore the filter to serviceable standards or simply replace the DPF costing thousands of dollars.

The FH2 effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding by simply connecting the appropriate fitting.

The FH2 process outperforms conventional DPF Cleaning technology both economically and in cleaning efficiency because the FH2 does not utilize pneumatic and/or thermal regeneration technology to remove soot and ash.

There is no need for large volume air compressors, air dryers and expensive electrical service upgrades and the entire

FH2 System occupies only a fraction of the floor space when compared to other technologies.

1. Quicker DPF Cleaning process time reduces costly downtime allowing you to get your customer back on the road in a few hours.

• 45 – 60 minutes for cars and light trucks

• 90 - 120 minutes for heavy trucks, buses and off road equipment

2. Cleaning efficiency consistently near 98.5%.

3. Cleans virtually any diesel particulate filter without the need for cutting, modification and/welding.

4. No particulate matter emissions (dust) or hazardous fumes in the workplace atmosphere making a safer, cleaner work environment.